Remote Monitoring

What is it?

Your compressor controller connects to Remote Monitoring Communication Device via Modbus. The communication device sends data to the cloud via cellular transmission. The data is segregated from the customer’s network.

What are the benefits?

This project provides real-time process and event data to allow us to evaluate critical operating parameters, thus enabling:

Quicker response: We will identify potential issues before failure

Increased first-time resolution: We will know which parts we need to bring the first time

Development of additional alarms: We will analyze data points to implement new warning parameters

What happens to the data?

Two important initiatives will support our Remote Monitoring: Asset Knowledge Base and Digital Mission Command Center

Asset Knowledge Base: This database is developed from recorded alarms along with technician-based input on resolution to equip our service teams to better respond to an event.

Digital Mission Command Center: This global team monitors operating parameters to identify signatures that lead to alarms and failures. We can then incorporate additional alarms to alert our service team about compressors operating in less than ideal states - such as short-cycling, inefficient operation or drawdown.

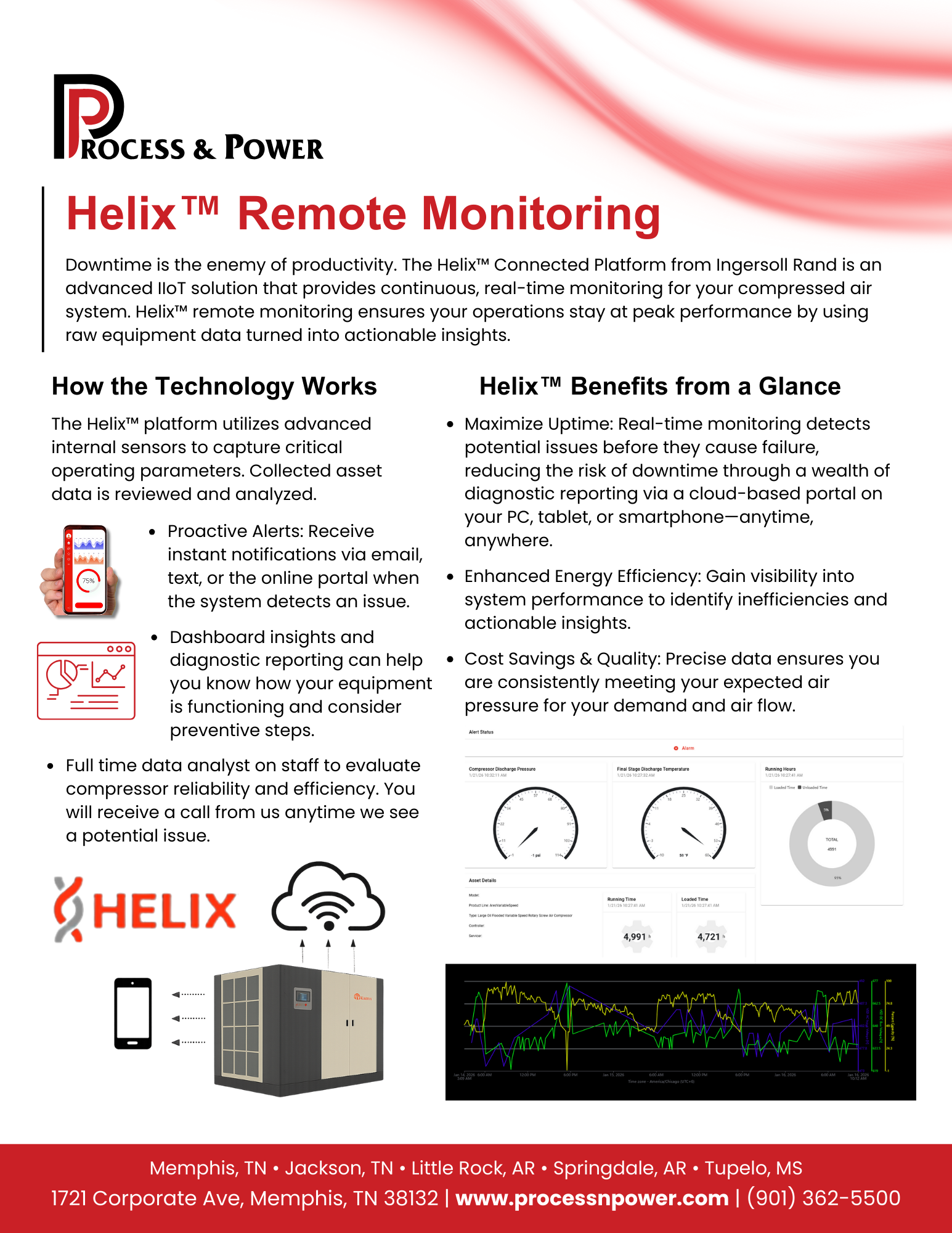

Live Remote Monitoring

Assets are monitored 24/7 by our Helix Connected Platform, allowing our service team to quickly detect when a problem or anomaly exists and begins to resolve immediately.

Increased 0 to 1st Trip Resolution

Gaining insight into an asset’s health prepares the service team for the issue, and allows time to send the anticipated parts for resolve with the technician before they arrive onsite.

Customer Portal Access

Visibility into day-to-day operational intelligence and asset information

Asset Insights and Historical Trending

Routine maintenance can be planned based on real time data. Data reports are accessible via online customer portal, including mechanical and coolant health, and CARE Service Events.

Service and Parts Notifications

Proactive alerts sent via email or text